News

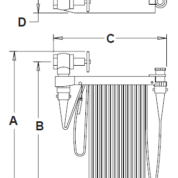

Design, manufacturing and supply of a complete fire skid & firefighting equipment for the new headquarter of the Worldwide Bank in Dakar, Senegal.

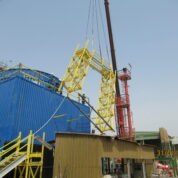

Design, manufacturing, erection, commissioning of a high capacity cooling tower in ATEX area in SENEGAL.

Design, manufacturing, erection, commissioning of a high capacity cooling tower in ATEX area in SENEGAL:

- Cell dimensions 10.2 m x 10.2 m x 8 m

- Water inlet : 1134 m³ / h

- Air outlet : 306 m³ / h

Oil Refinery in West Africa.

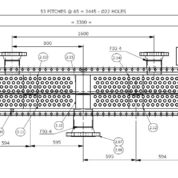

Supply of two complete sets of bended tubes for exchangers:

Production & delivery of two complete sets of bended tubes for exchangers:

- 1 exchanger with carbon steel tubes

- 1 exchanger with brass tubes (admiralty brass ASME SB 111-443)

Oil Refinery in West Africa.

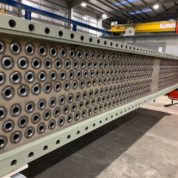

Design, production, delivery of two air cooled heat exchangers.

Design, production, delivery of 2 finned tubes exchangers:

- Waste material cooler :

- 406 tubes, extruded aluminium fins

- L 9600 ; l 3600 ; h 1200 ; weight 16800 kg

- Stabilization condenser :

- 55 tubes, extruded aluminium fins

- L 9620 ; l 820 ; h 580 ; weight 2700 kg

Oil Refinery in West Africa.

Design, supply, installation & commissinning of a complete steam boiler in Mali.

Design, supply, installation & commissioning of a complete steam generation installation (boiler 5T/h at 12 bars, deaerator, steam & condensates collectors, gasoil tank, water treatment, economiser, etc..

New containerboard factory in Mali

4 steam turbine generators inspections.

Expertise of 4 steam turbines + gearboxes, done by 2 technicians :

- three units of 4.5MW turbine generators,

- one unit of 1.8 MW turbine generator.

Gate valves supply for Senegal.

Supply of gate valves set (incl. flanges, seals and nuts and bolts) for steam manifold.

DN 150, PN 100, delivery under 10 days.

Smoke-tubes boiler repair

(16 bars, 210 °C) in Djibouti.

Due to heavy fuel presence in water circuit of the boiler, the smoke-tube boiler was damaged.

We performed chemical cleaning using acid, degreasing and alkalin baths.

Fire-box leaking was repaired with certified welds.

The boiler has been tested.

The water circuit has been isolated from the defective heat exchanger with the implementation of an additional heat exchanger.

Restart of the boiler.

HT economizer supply for a power plant in Morocco.

Supply of one double-coil economizer high temperature.

Manufactured by Greens Power Ltd in Wakefield (UK).

The coil is composed of 12×2 tubes.

The coil : 12.4m length, 1.4m width and 2.2t weight.

LT economizers supply for a power plant in Morocco.

Supply of two double-coils economizers low temperature.

Manufactured by Greens Power Ltd in Wakefield (UK).

Each coil is composed of 12×2 finned tubes.

One coil : 13.5m length, 1.6m width and 3.5t weight.

Supply of heat exchanger coils for a Cameroon sugar factory.

Supply of heat exchanger coils for the refurbishment of a vertical mixer.

Manufactured by Greens Power Ltd in Wakefield (UK).

Conception and manufacture of the coils with definition of the replacement operations routing.

Each of the 13 coils has a 4m diameter. Total weigth of 5t.

Economizers replacement in a Gabon sugar factory.

Work supervision for the replacement of the used economizer by the new one (with new finned tubes technology).

Dismounting of the used economizer, refurbishing of the structure and the casing, assembling, connections, commissioning and pressure test.

Seetblower refurbishing.

Carbon steel finned tubes economizer supply for a Gabon sugar factory.

New technology for the replacement of a cast iron economizer.

Manufactured by Greens Power Ltd in Wakefield (UK).

Economizer is composed of 6 coils of 13 finned tubes each.

The supply includes inlet and oulet headers as well as spare parts.

Total weight is 6 tons.

Economizers replacement in Cameroon sugar factory.

Work supervision for the replacement of the used economizer by the new one (with new finned tubes technology).

Dismounting of the used economizer, refurbishing of the structure and the casing, assembling, connections, commissioning and pressure test.

Carbon steel finned tubes economizers supply for a Cameroon sugar factory.

New technology two economizers for the replacement of two cast iron economizer.

Manufactured by Greens Power Ltd in Wakefield (UK).

Each economizer is composed of 6 coils of 8 finned tubes for the first one and 9 tubes for the second economizer.

The supply includes inlet and outlet headers as well as spare parts.

Total weight is 13 tons.

Power generator expertise in Gabon.

Expertise on a SACM (Wartsila) generator UD30V12, 1250kW, including the anciliaries.

Expertise in order to define the actions plan to refurbish the power installation to make it operational.

Engine expertise in a Djibouti power plant.

Technical expertise on a 16CM32 MAK (Caterpillar) engine, 7450kW.

Expertise of the cylinders following the cylinder liner cracking.